Puffs of water vapor soared as the pot for boiling the cloth was lifted. The fire which is not too big has also completed its task for almost 2 hours. The pot contained at least seven to ten rolls of cloth. The fabrics are neatly wrapped and wrapped with adhesive so they don't leave any space. The hot roll of cloth is allowed to cool in order to continue the process.

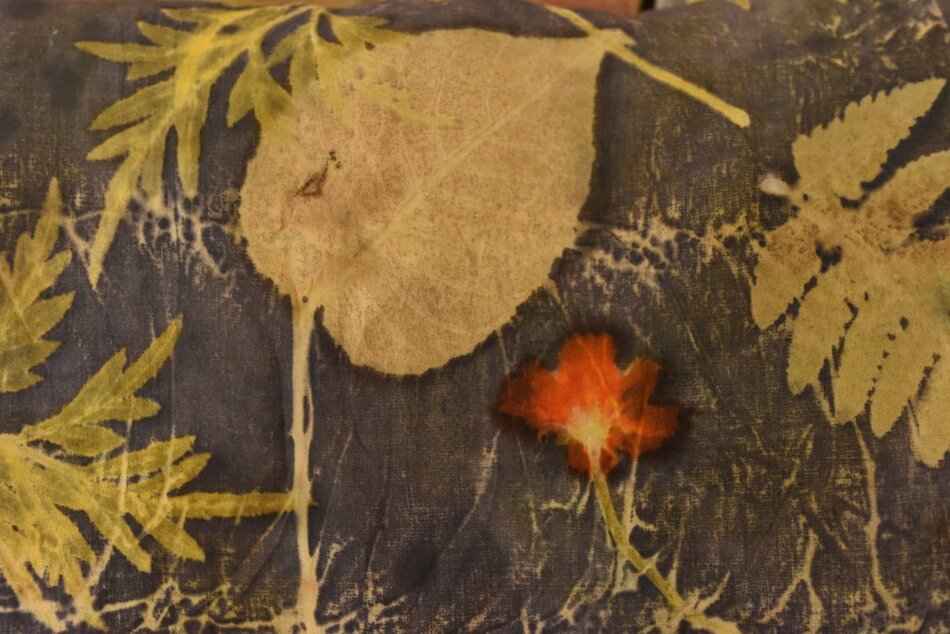

This process is one of the steps taken to create a piece of cloth that has a plant motif. Eco-print, as the public calls it. Eco-printing is the process of creating a plant-patterned fabric, where the motif is derived from native plants. Eco-print maintains the color and shape of the plants that are the motif.

Iwan Risnasari, a lecturer from the Faculty of Forestry, University of North Sumatra (USU), plunged into the world of Eco-print in 2019. The underlying reason for pursuing Eco-printing came from the intention to do community service as one of the lecturers' duties in implementing the Tri Dharma College. She pays attention to the abundant resources around the community to be used as the basic material for carrying out Eco-prints.

Almost every day, the woman who was born in Bondowoso, August 19, 1973, works diligently with the Eco-print method to create various products. With the help of several assistants who helped her, Sari, as she is familiarly called, produces Eco-prints for hijabs, pashminas, tunics, shirts, and other clothing products. In addition, he also applies the Eco-print method to produce glasses, book covers, key chains, shoes, and bags. All of these products are done manually without the help of sophisticated equipment.

On the other hand, product workmanship that uses manual labor and natural materials makes it a product with a high selling value. Eco-print products begin with the search for basic materials. Fabrics made from natural fibers are preferred over synthetic fabrics, because fabrics with natural fibers have a texture that can bind colors more strongly.

After cleaning, the cloth then goes to the mordant stage (binding dye so it does not dissolve in water or moisture), with the aim of opening the pores of the fabric so that the coloring can be evenly disseminated. After that, leaves or other plant parts that will be used as motifs are affixed to the cloth. To keep the position of the leaves from shifting, the cloth is covered again with a layer of blanket cloth and then rolled up to solidify. The roll will then be steamed. The steamed cloth is then dried by aerating. The fabric should not be dried in direct sunlight because it will damage the coloring and motifs made. The drying process can take one to two weeks.

The plants used come from various types, such as Teak, Secang to Gambir. The plant parts used also vary, ranging from leaves or flowers, as long as they can produce colors and have good motifs. She said, Eco-printing will produce less waste and uses less chemicals. In addition, it can also improve the community's economy because the process can be carried out in the home industry. Abundant basic materials make it easier for people to develop Eco-prints.

Some of these indicators encourage her to carry out community service activities in various places. Together with the Chair of the USU Forest Products Technology Department, Arif Nuryawan, S.Hut., M.Si., PhD, and Dr. Bejo Slamet, S.Hut., M.Si., Sari carried out a series of community services. Pangkalan Susu and Lubuk Kertang in Langkat Regency, and Sei Glugur in Deli Serdang Regency are some of the locations for community service that they do.

In addition, independently, Sari also established an Eco-print business unit called Nauli Eco-print. Together with his team, Nauli Eco-print has conducted many Eco-print trainings to the community. Most recently, the Nauli Eco-print provides training to refugees under the auspices of the International Organization for Migration (IOM), the wing of the United Nations (UN) organization. Refugees from Somalia, Sri Lanka, and Afghanistan are trained to be able to produce Eco-print products on June 21-25, 2021.

This woman is determined to continue to do research in the field of forest product utilization, namely Eco-print. She and her team continue to try to test various plants that are possible as the basic ingredients for making Eco-print products. She believes that her efforts will open up public knowledge about Eco-printing as a promising business. (RR)